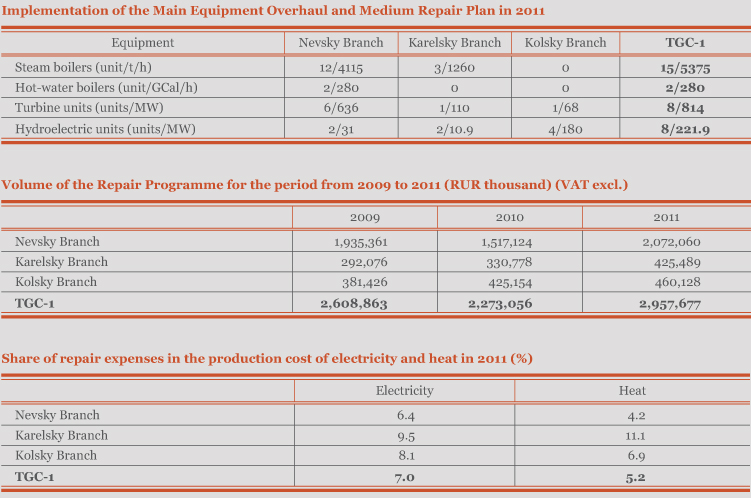

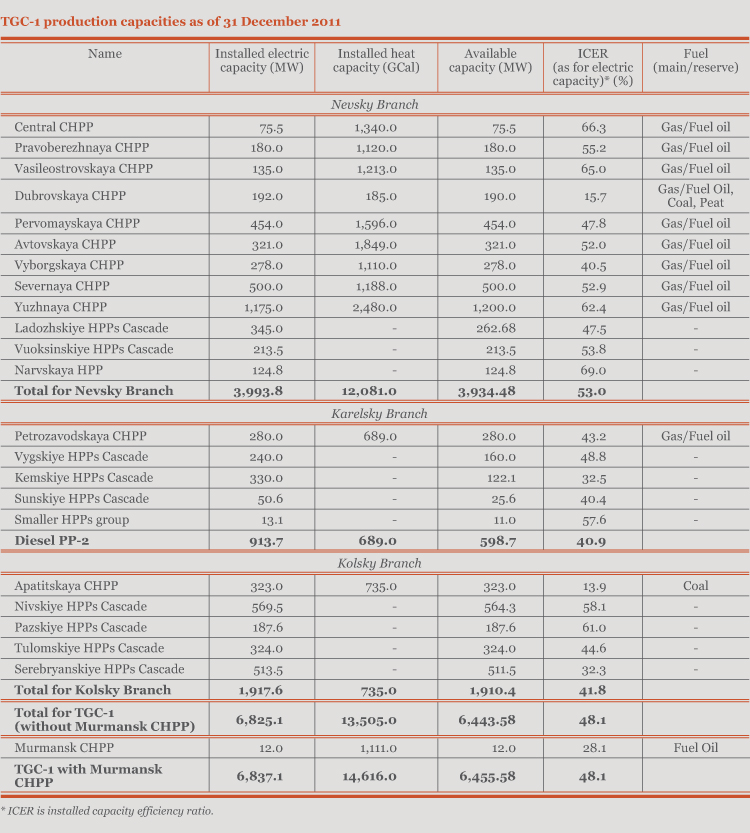

3.1. Production Capacities

The main generating units of TGC-1 are 55 power plants, including 41 HPPs and 14 CHPPs, and one subsidiary, Murmansk CHPP. At the end of 2011, the Company’s installed electric capacity was 6,837.1 MW and installed heat capacity was 14,616.0 GCal/h (including Murmansk CHPP).

Installed capacity changes in 2011:

- 1) Increased at the Yuzhnaya CHPP resulting from commissioning of the CCGT-unit at plant No. 4 with installed

electric capacity of 425 MW; - 2) Increased at the Pervomayskaya CHPP resulting from commissioning of the CCGT-unit No. 1 with installed

electric capacity of 180 MW and decommissioning of turbo-generator No. 6 with installed electric capacity of

50 MW; - 3) Increased at the Lesogorskaya HPP of the Vuoksinskiye HPPs Cascade by 6 MW resulting from remarking of the

hydro generating unit No. 2 after the retrofit; - 4) Reduced by 2 MW resulting from the sale of property rights of the Valaam diesel power plant to FGC of the UES.

Available capacity changes for 2011:

- 1) Reduced at the Dubrovskaya CHPP resulting from increase of seasonal restrictions;

- 2) Increased at the Yuzhnaya CHPP resulting from negative seasonal restrictions at the CCGT unit of plant No. 4;

- 3) Increased at the Volkhovskaya HPP of the Ladozhskiye HPPs Cascade resulting from the reduction

of seasonal

restrictions; - 4) Increased at the Lesogorskaya HPP of the Vuoksinskiye HPPs Cascade resulting from re-evaluation

of the hydro

generating unit No. 2 after the retrofit.

3.2. Electricity Generation

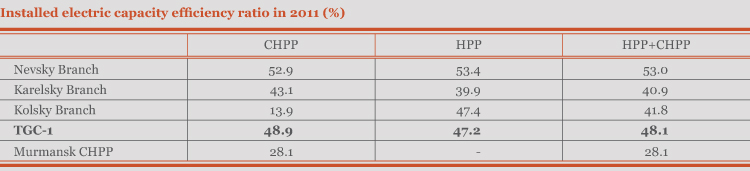

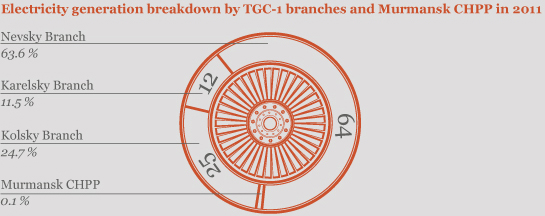

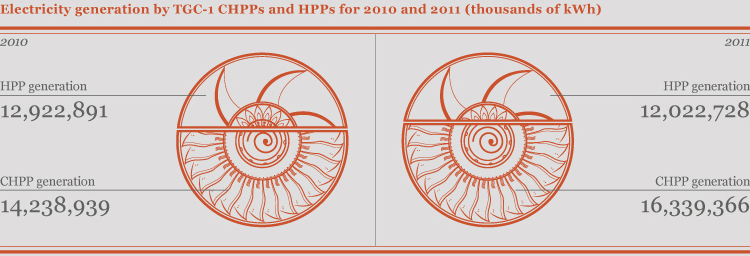

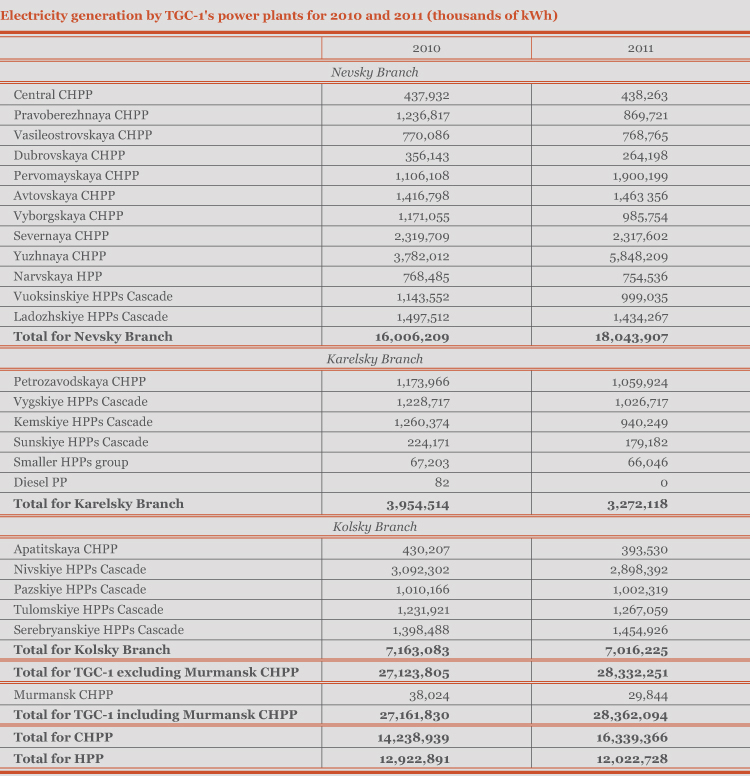

In 2011, the overall electricity generated by TGC-1, including the Murmansk CHPP, increased by 4.4% compared to 2010 and equaled 28,362.1 million kWh. Generation by the Nevsky Branch increased by 12.7%. The Karelsky Branch generation volume decreased by 17.3 %, and Kolsky Branch generation decreased by 2.1 %.

Installed electric capacity efficiency ratio for TGC-1 rose to 48.1 % in 2011; it was registered at the level of 47.2 % for HPP, and 48.9 % for CHPP.

Proceeding from results of 2011 fiscal year, TGC-1’s CHPPs generation increased by 14.8 %, HPPs generation decreased by 7 % due to the low water level compared to average long-term values in the Republic of Karelia and the Leningrad Oblast. Commissioning of new power generating units at the Yuzhnaya CHPP and Pervomayskaya CHPP increased significantly the Company's overall generation volume. Newly commissioned units accounted for 11.8 % of overall generation.

3.3. Heat Generation

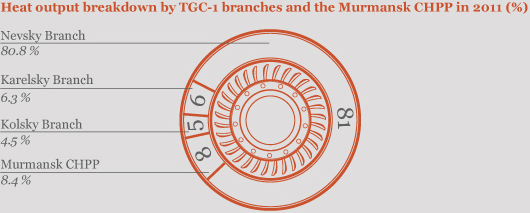

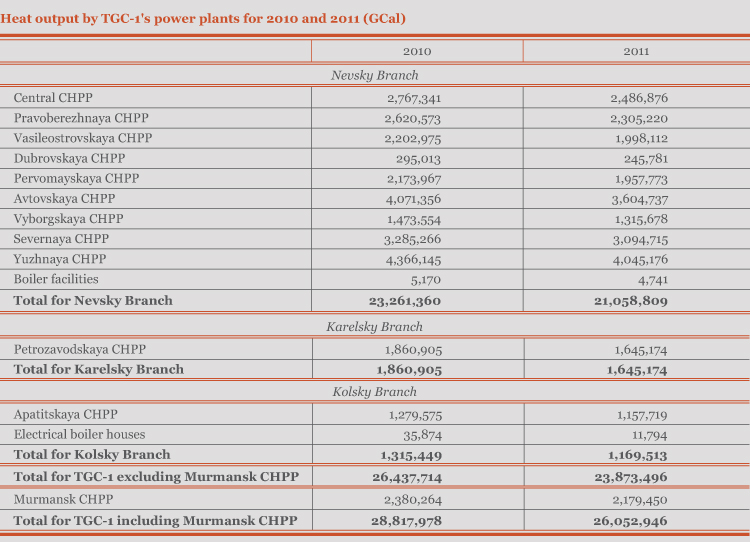

TGC-1's heat output in 2011 was 26,052.9 thousand GCal, a reduction of 9.6 % compared to 2010 due to higher temperatures during the heating season.

The output of the Nevsky, Karelsky and Kolsky branches was reduced by 9.5 %, 11.6 % and 11.1 % respectively. Heat output of the Murmansk CHPP decreased by 8.4 % compared to 2010.

3.4. Analysis of Fuel Consumption by TGC-1's CHPPs

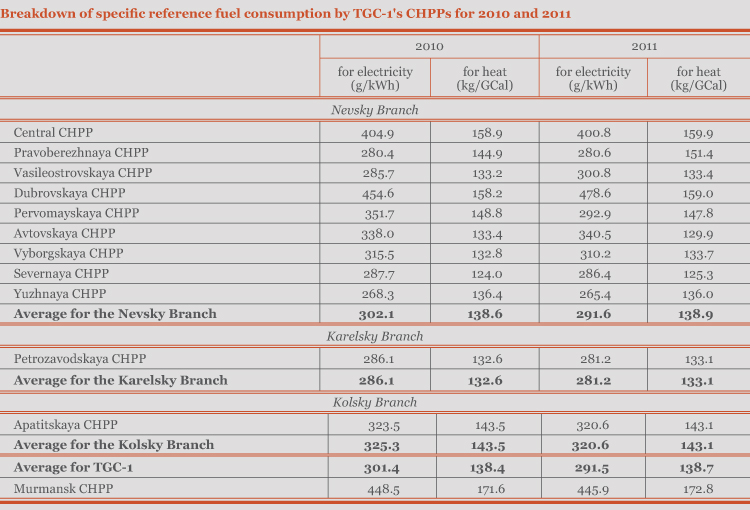

The specific reference fuel consumption is a main parameter used for assessing fuel consumption at TGC-1’s CHPPs. In 2011, the specific reference fuel consumption for delivered electricity amounted to 291.5 g/kWh, which is 3.3 % less compared to 2010. The specific reference fuel consumption for delivered heat increased by 0.3 % for the whole year up to 138.7 kg/GCal.

Reduction of the Company’s overall specific reference fuel consumption for delivered electricity was due to commissioning of the new CCGT units with lower reference consumption.

3.5. Energy Saving and Energy Efficiency

In 2011, TGC-1 approved the programme of energy saving and energy efficiency improvement for 2011–2013. As a result of activities aimed at improving energy efficiency and reducing production and operating costs, the following volumes were saved in 2011: 28,013 and 233 thousand kWh for the Nevsky Branch; 1,540 and 32 thousand kWh for the Kolsky Branch; 277 and 6,570 kWh for the Karelsky Branch, with an estimated annual savings from the cooling tower renovation total of 1,180 thousand.

3.6. Repair Programme

The Company’s 2011 Repair Programme is focused on maintaining the basic generating facilities in full operational conditions at optimal maintenance and repair costs.